HONG KONG.- A research team from

The Chinese University of Hong Kong (CUHK)’s Faculty of Engineering has recently devised a novel fabrication method for soft robots, using adhesive tape and magnetic microparticles with simple cutting and embedding. This structural fabrication, like 3D origami, provides a foundation for developing modular soft robots that potentially enable flexible shape deformation and multifunctionality in environmental sensing and medical tasks, after assembling different functional modules.

Origami-like structure starts from simple transfer of magnetised patterns

Soft robots are known for their dexterity in making structural changes that allow them to grasp objects and perform targeted drug delivery. There is a huge range of potential future applications for them. Coming up with a programmable modular design that brings different functional modules with varying materials together, however, has remained a key challenge, as has integrating them into one soft robot that can be adjusted as needed. Furthermore, to change shape under magnetic fields, magnetic microparticles have to be arranged in complex patterns, which poses a major challenge even to a soft robot of just a few centimetres long.

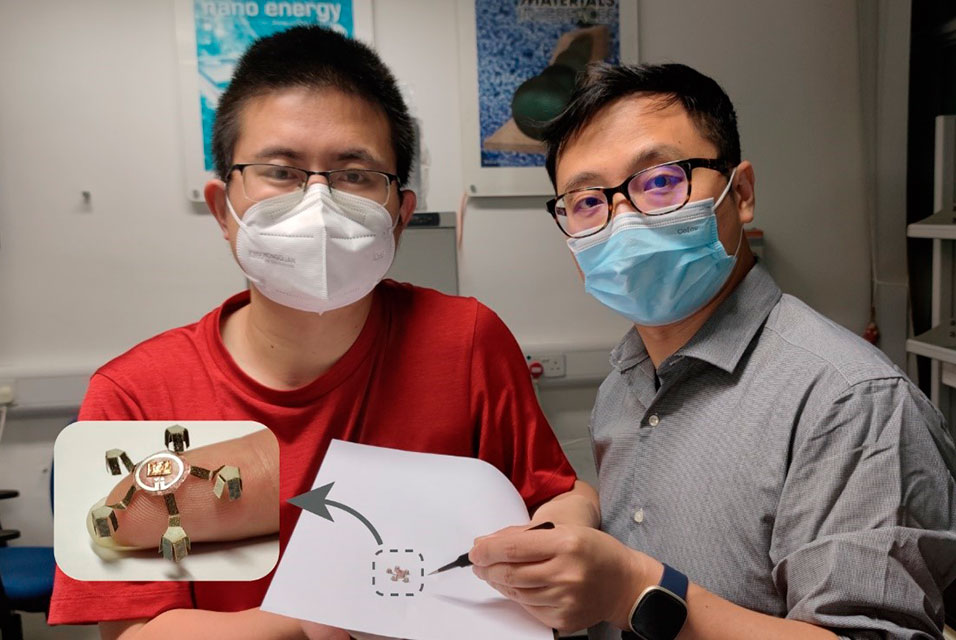

Professor Li Zhang from the Department of Mechanical and Automation Engineering, CUHK and his team were inspired by temporary tattoos, decals printed on transfer film and transferred onto the skin by applying pressure and moisture. The team borrowed the concept and programmed the soft robots for synthesis and transfer of prescribed NdFeB patterns onto PEI tape, commonly used for label stickers, to form a patterned template that can be inserted onto a more adhesive double-sided tape. Layer by layer, the magnetised NdFeB patterns from the template are transferred to the double-sided tape. The complete pattern is cut out from the double-sided adhesive tape using a laser, configuring the body of the magnetic soft robot.

Magnetisation will drive the deformation of the 2D geometry on the double-sided tape to 3D geometry, like 3D origami. After stimulation with an external magnetic field, the soft robot can undertake a variety of continuous movements like folding and grasping.

Seamless multiple-module integration creates medical and industrial potential

The strong tackiness of the double-sided tape favours multi-material fabrication, and compatibility with programmable magnetisation paves the way for biomedical and industrial applications. The research team has successfully incorporated various functional modules seamlessly into the network of the soft robot by adhesion with no additional connecting steps required, allowing it complete tasks including temperature sensing, UV light sensing, pH sensing, electric conduction, oil sensing, circuit repair and ulcer treatment in stomach.

Professor Zhang said, “As an investigation for in vivo biomedical application of the modular magnetic soft robot, we have demonstrated a simulation of therapy patch transfer in treating gastric ulcers. The soft robot, controlled by magnetic fields, can move along, stretch itself against the uneven gastric wall, and release the therapy patch on the surface of an ulcer. In the future, more electronic components, such as silicon infrared LEDs, transistors and near-field communication coils, can be integrated to improve the versatility and intelligence of the soft robots.”

The research team also includes the team of Professor Jiachen Zhang, from the Department of Biomedical Engineering at City University of Hong Kong, and the team of Professor Carmel Majidi, from the Department of Mechanical Engineering at Carnegie Mellon University. They commented that this achievement is an actualisation of the integration of a variety of functional components in a low-cost way, through a novel modular design that addresses key challenges in the development of soft robots and transforms them into a technology with a practical application in everyday life.

The project has been supported by the Research Grants Council (RGC), the HKSAR Innovation and Technology Commission (ITC), the Croucher Foundation, the Chow Yuk Ho Technology Centre for Innovative Medicine, the CUHK T Stone Robotics Institute, the SIAT-CUHK Joint Laboratory of Robotics and Intelligent Systems, and the Multi-Scale Medical Robotics Center (MRC), InnoHK, at the Hong Kong Science Park. The findings have been reported in Science Advances.